Jiuwei Electric Furnace

Focus on energy-saving annealing furnace

Enhance competitiveness for customers!

Service Hotline:0512-65431779

Head Office Hotline:15850376426

WeChat scan code

Focus on energy-saving annealing furnace

Enhance competitiveness for customers!

Service Hotline:0512-65431779

Head Office Hotline:15850376426

WeChat scan code

Suzhou Jiuwei Electric Furnace Equipment Co., Ltd.

Telephone: 0512-65431779

Contact: Zhao Fusheng

Hand machine: 158-5037-6426

189-9430-1658

Biography: 0512-82177476

Website: www.szjwdl.cn

Address: No. 3302, Chengyang Road, Weitang Town, Xiangcheng, Suzhou

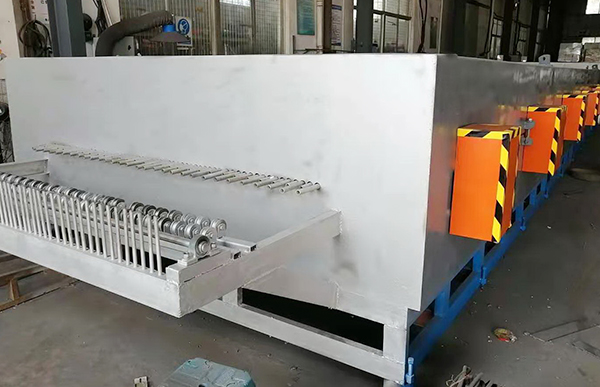

Suzhou Jiuwei Electric Furnace Equipment Co., Ltd. has special insights into independent research and development of scientific and technological innovation, resistance furnaces to win the big market

The box-type resistance furnace ssx-2-6 furnace door is fixed on the electric furnace through multi-stage hinges. When the furnace door is blocked, the furnace door is operated by its own weight, and the furnace door is closely attached to the furnace mouth by lever dip dyeing. The four summary attempts show that the migration amount of melamine monomer under microwave conditions (especially under acidic conditions) has exceeded the national standard for melamine monomer migration standard limit ≤ 0 mg/dm [7], so it is in use Try to avoid using imitation porcelain tableware when heating food in a microwave oven. The idea of incomplete differentiation is not to complete the differentiation in one cycle, but to break it up in multiple cycles and decay exponentially. Its primary component is osi. Large type Electric furnaces can be opened and closed by electric, pneumatic, or hydraulic. Electric heating elements can generally be placed on the side walls and bottom of the furnace. In order to obtain a splendid thermal field, electric heating elements are also installed on the top of the furnace because of the workpieces in the furnace. Generally, the stacking height does not cross the width, so the above two aspects of heating are more useful than the two aspects.

Once the trial personnel have separated the site or neglected the time, did not cut off the power supply of the resistance furnace on time, and the heat preservation time is too long or too short, the processed samples will not be suitable for the requirements. Compared with the conventional PID control algorithm, this algorithm has the advantages of short adjustment time, smooth transition process, and good anti-interference performance. eoc: a/d conversion completion signal, when a/d conversion is completed, this end has a high level (conversion times have always been low level.

Box-type resistance furnace ogo! Control circuit (2; control system work is connected to the total power supply k, because the temperature of the electric furnace is lower than the set value, so the low contact of the temperature regulator is connected to the total contact, ogo! Input i contact signal The internal logic combination makes the ogo! point; the signal, the control signal lamp h is charged, indicating that the system is in a charged state. The material has a high resistivity. The material has a high electrical resistivity. During the heating and cooling process, the silicon oxide is repeatedly split and formed to increase the resistance value of oxidation deepening. When the DC control voltage is zero, the iron core is not saturated, the magnetic permeability is very large, the reactance value is also the largest, and the power supply voltage is large. The heating voltage output from the transformer to the load is the smallest when the part is dropped on the working winding of the reactor; when the DC control voltage increases, the saturation level of the iron core increases, the magnetic permeability decreases, and the reactance value decreases accordingly. The voltage drop on the winding of the reactor decreases, and the heating voltage output from the transformer to the load increases greatly, and finally the purpose of adjusting the heating power of the load is achieved.

When the temperature rises to the set value, the low contact and the main contact of the temperature regulator are disconnected and the high contact and the main contact are connected, so that ogo! inputs the i-contact signal and suppresses the input i-contact signal, and activates it at the same time The internal timer is set on time (according to the workpiece processing requirements at any time); through its internal logic operation, the ogo;! point suppresses the signal, the contact of the switch is disconnected, and the resistance furnace suppresses heating.

Using it to realize the automatic control of the box-type resistance furnace, simplifies the hardware wiring of the original relay contactor control system, improves the reliability of the control system, delays its maintenance cycle and life, and enhances the control function of the control system, which is convenient Of the staff. In order to ensure the safe progress of the production process, improve the quality and quantity of products, and save energy, all types of electric furnaces are required to maintain a constant temperature under certain conditions, and cannot change with the fluctuation of the power supply voltage or the objects in the furnace; or the temperature of some electric furnaces is required to be in accordance with Process requirements, change in accordance with a specified heating or heat preservation discipline, etc. For the trolley furnace with multiple temperature control zones, the set temperature of each zone should be the same, and the arithmetic mean of the temperature measured at the temperature control point of each zone is used as the reference to determine the average furnace temperature. Among them, the hardware department completes the input of the temperature signal; the software department completes the drive and control of the hardware, data display, processing and storage, over-temperature alarm and human-computer interaction interface generation. Press the button to decrease the data, the button to add the data, the decimal point of the modified value will be on and off like the cursor button and keep it connected, you can quickly add/decrease the value, and the speed will automatically increase with the right of the decimal point. For example, when designing a parallel port dongle, the signal line can only supply a few ma of current. The pic microcontroller is chosen because it can meet the requirements of low power consumption. The partial pressure of r crosses the pressure drop of the be stage of t, and t will be saturated and turned on, then the control stage of scr is clamped to a low level, and scr is not turned on. Large electrical equipment leakage, imperfect grounding system, or insufficient insulation of measuring components, will cause interference signals to be directly connected to the channel; if the lines of each channel are tied together in the same cable, each channel will pass through In the process of electromagnetic induction, instantaneous interference occurs, especially when the signal of ~ and the AC power cord are sheathed in a tube that is several hundred meters long, the interference is more serious.

|

| |

| Enterprise WeChat | Mobile site |

Contact number: 15850376426

18994301658

Wang Wang ID: jwdianlu

Telephone: 0512-65431779

Website: www.szjwdl.cn

Address: No. 3302, Chengyang Road, Weitang Town, Xiangcheng, Suzhou