Jiuwei Electric Furnace

Focus on energy-saving annealing furnace

Enhance competitiveness for customers!

Service Hotline:0512-65431779

Head Office Hotline:15850376426

WeChat scan code

Focus on energy-saving annealing furnace

Enhance competitiveness for customers!

Service Hotline:0512-65431779

Head Office Hotline:15850376426

WeChat scan code

Suzhou Jiuwei Electric Furnace Equipment Co., Ltd.

Telephone: 0512-65431779

Contact: Zhao Fusheng

Hand machine: 158-5037-6426

189-9430-1658

Biography: 0512-82177476

Website: www.szjwdl.cn

Address: No. 3302, Chengyang Road, Weitang Town, Xiangcheng, Suzhou

Why do annealing furnaces need to be baked?

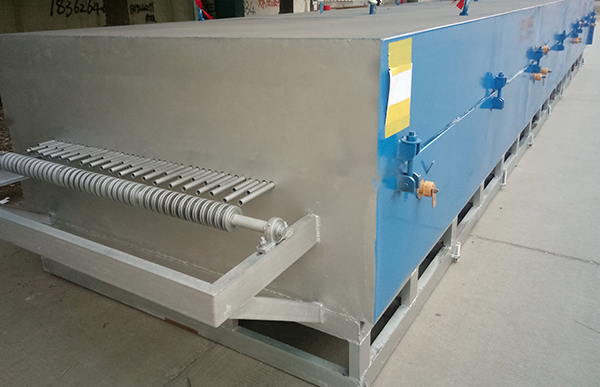

The skeleton of the annealing furnace is welded by various section steels. The outer frame is made of channel steel as the main beam, the coaming plate is made of cold thin plate, the trolley is made of channel steel as the main beam, and the bottom plate and front and rear end plates are medium plates.

Transmission part: The trolley is driven by a motor and a speed reducer through a chain to drive a set of driving wheels at the front end. The furnace door drive adopts a combination of a worm gear reducer and a motor for electric lifting.

Sealing: The trolley and the furnace body are sealed with a labyrinth structure, and there is an automatic sand-sealing knife sealing device on the side of the trolley.

The furnace door is sealed with a roller-type compression and spring compression automatic mechanism. The furnace body part adopts a better refractory brick structure to ensure the sealing of the furnace. High-alumina bricks are used in the pressure-resistant part of the trolley, and thermal insulation bricks are added to the lower part for heat preservation.

Combustion system: Install several burners on both sides of the oil furnace, and the heat flow reciprocates in the furnace to ensure the uniformity of furnace temperature. Automatic type and semi-automatic type can be selected according to needs.

Exhaust preheating device: A fume preheating device is installed at the upper end of the furnace. When the flue gas in the furnace passes through the preheater, it is preheated by the fan into cold air, and then sent to the burner by the pipeline to support combustion, and A manual butterfly valve is installed at the outlet, which can adjust the pressure in the furnace. It is widely used in the process of heating, cooling, condensation, evaporation and other industrial sectors such as chemical industry, petroleum, food, metallurgy, machinery, light industry, electric power, shipbuilding, papermaking, mining, medicine, and central heating.

1. The new furnace is manufactured at room temperature, and the refractory materials and binders in it all have residual moisture and need to be removed;

2. The new furnace has not passed the test of high temperature. If it is put into use immediately, it will be deformed or even cracked due to the heating speed being too fast. The furnace is heated slowly for a long time and the heating temperature is gradually increased. The purpose is to eliminate the above-mentioned unfavorable factors.

|

| |

| Enterprise WeChat | Mobile site |

Contact number: 15850376426

18994301658

Wang Wang ID: jwdianlu

Telephone: 0512-65431779

Website: www.szjwdl.cn

Address: No. 3302, Chengyang Road, Weitang Town, Xiangcheng, Suzhou