RGZ series continuous roller type oxygen-free, bright annealing furnace

1. Description:

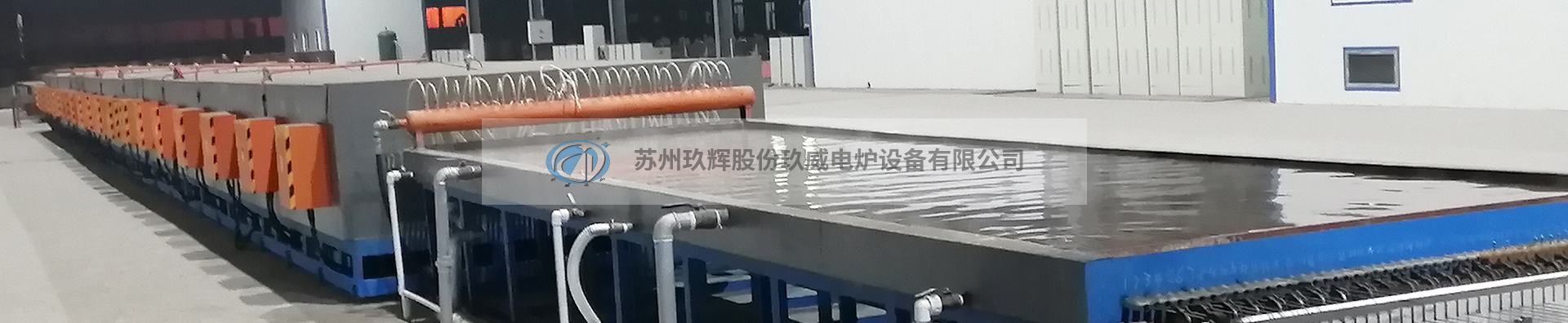

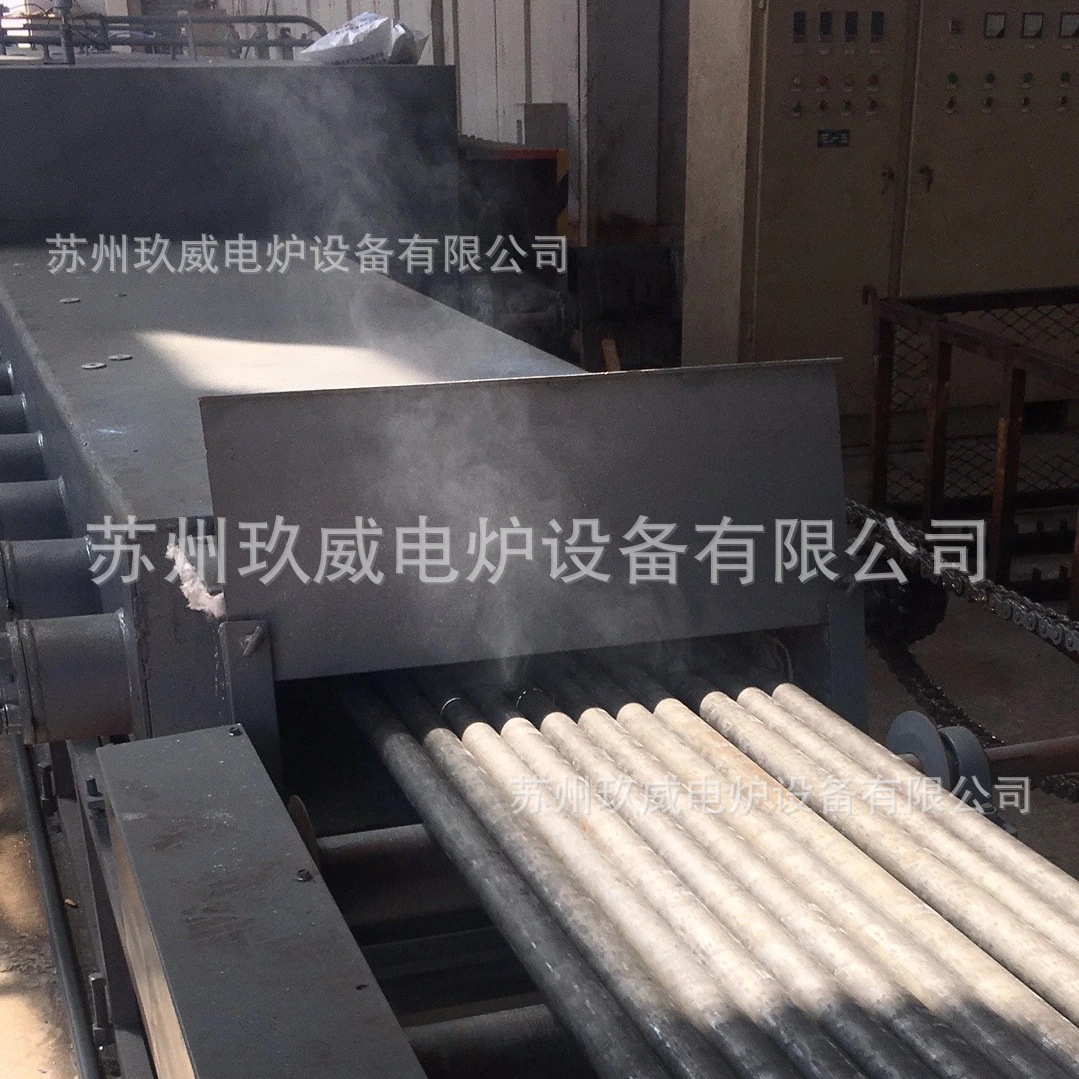

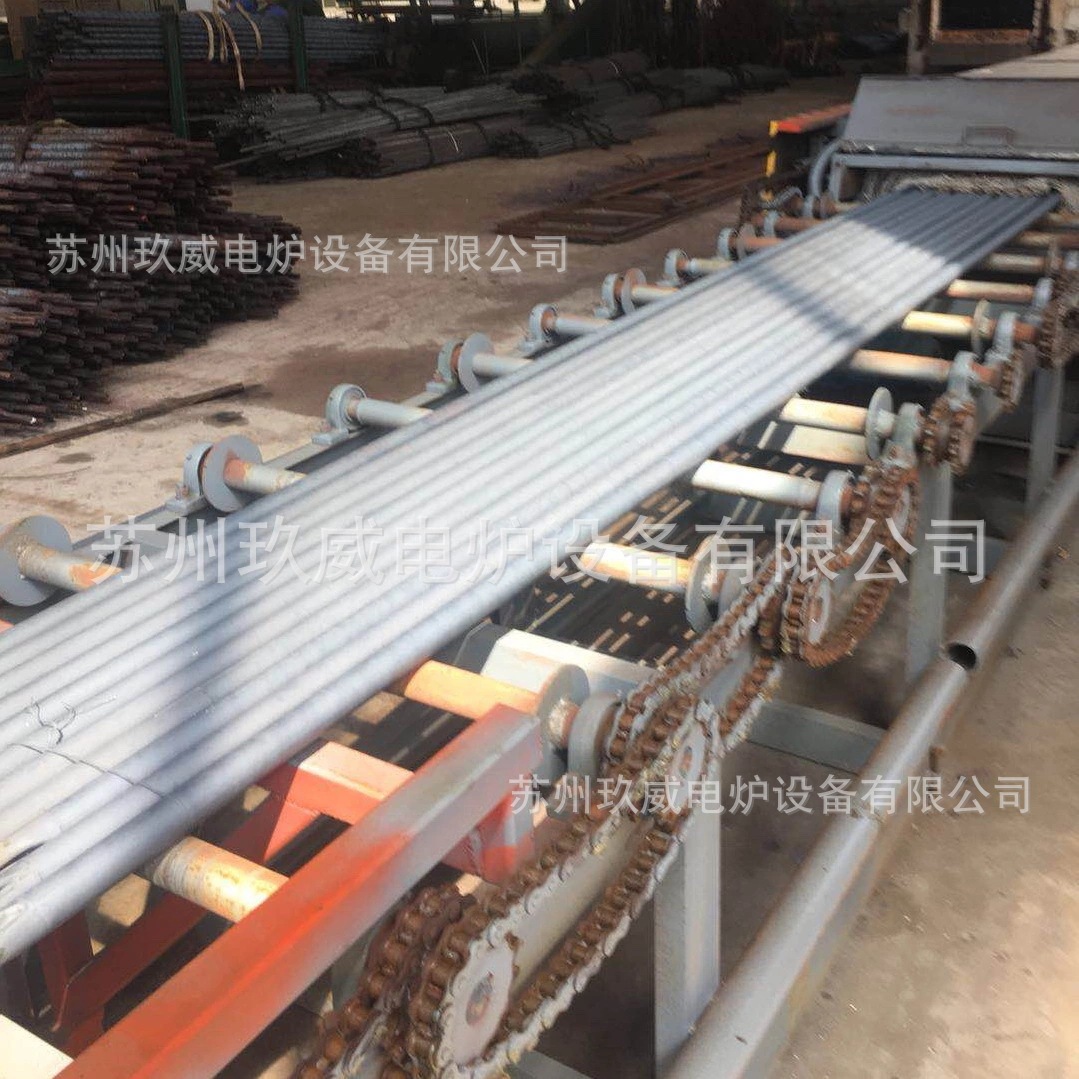

The complete set of equipment for roller furnace is divided into feeding rack, preheating area, heating area, heat preservation area, water cooling area, discharging rack, automatic unloading rack and supporting nitrogen generator and ammonia decomposition.

2. Specifications (the length can be determined, according to the output demand):

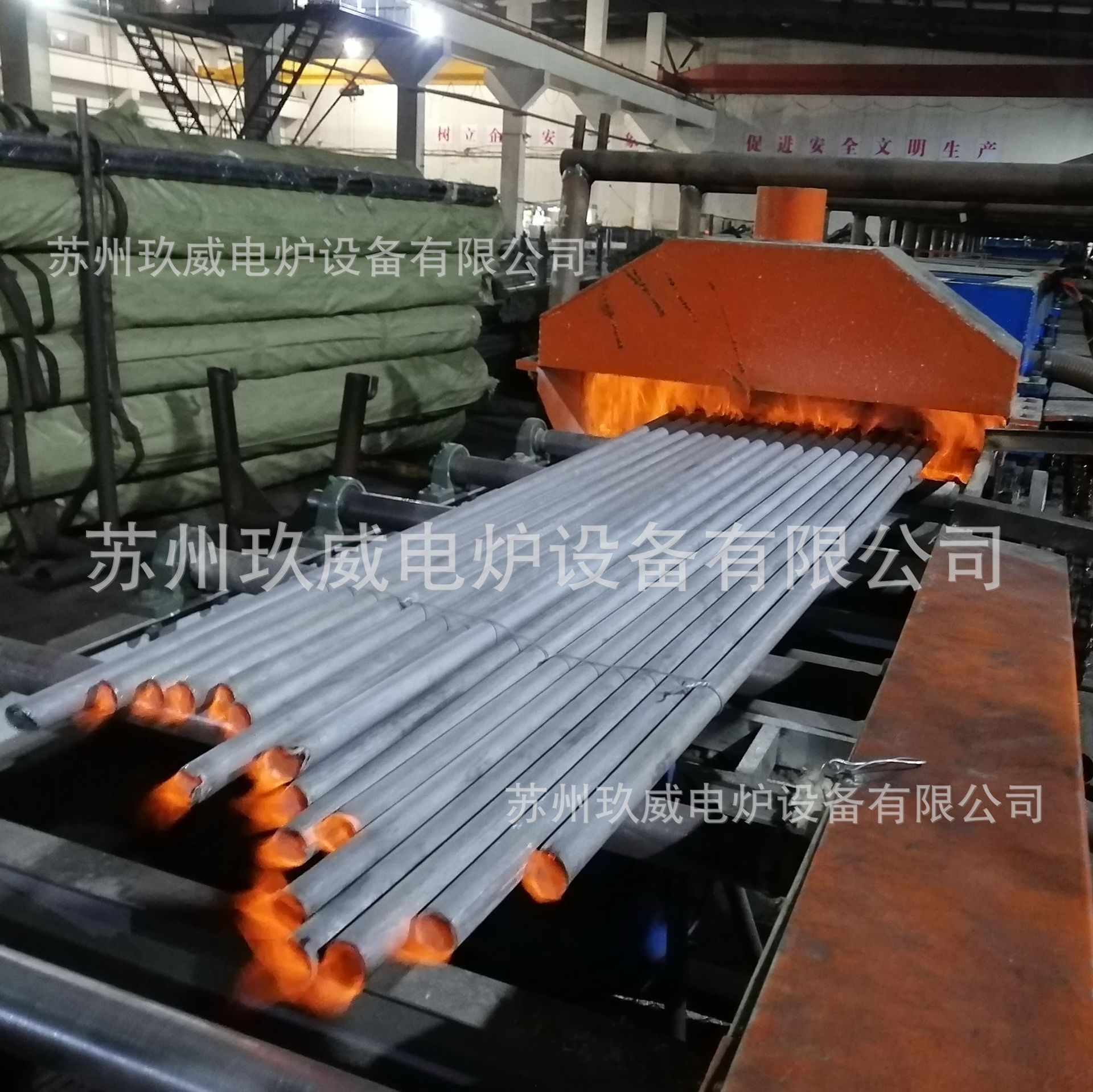

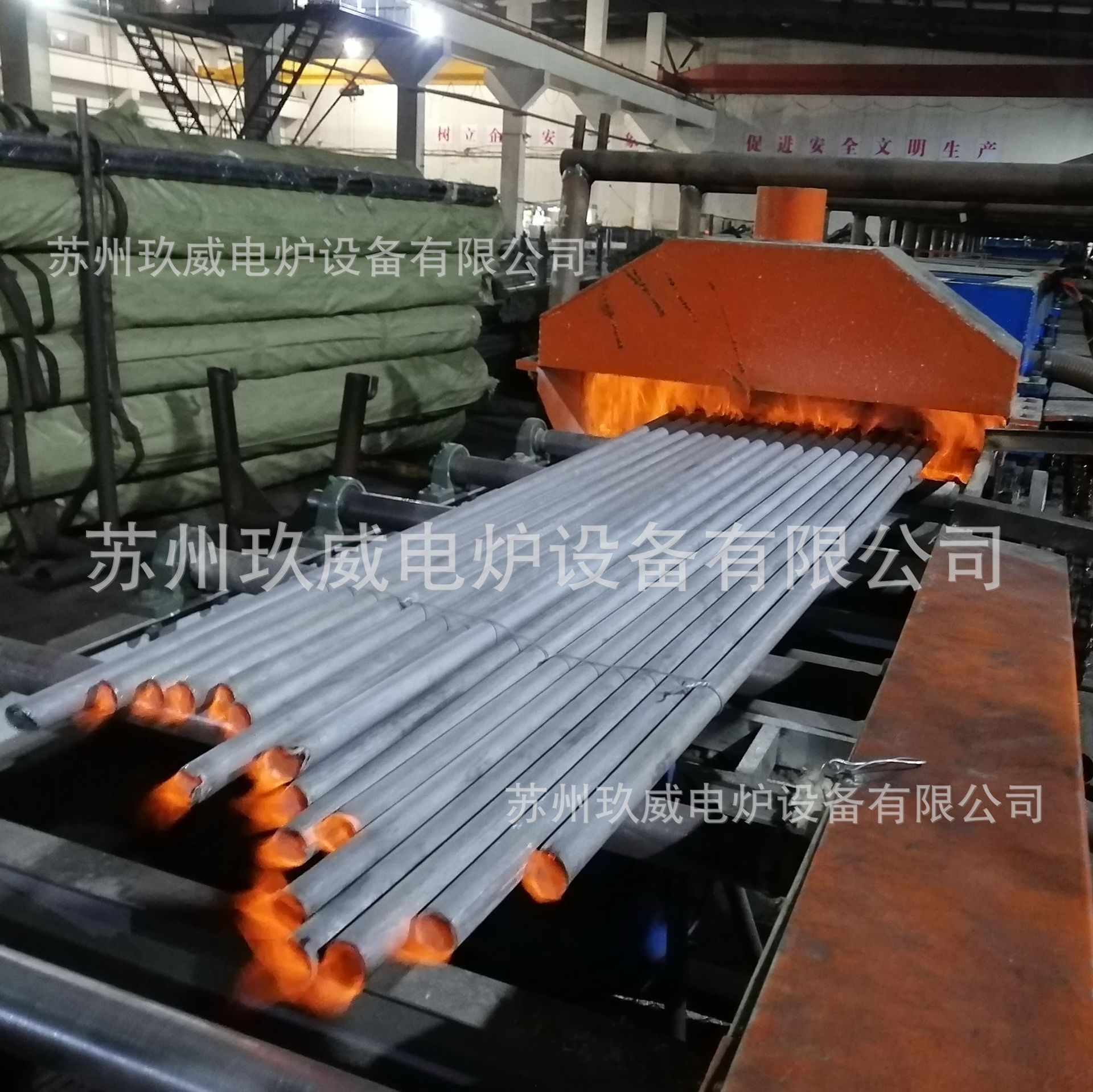

Generally effective widths are: 600mm, 800mm, 1000mm, 1200mm, 1500mm, length <15 meters, output 0.5-2T/H; conventionally used for aerobic, oxygen-free, bright annealing and normalizing of steel pipes; copper pipe annealing, steel plate Annealing, quenching, solid solution and quenching of stainless steel pipe; solid solution and quenching of stainless steel plate.

3, The main technical parameters:

1 | power | 90-480KW |

2 | Operating temperature | 《1100℃ |

3 | Heating effective size (mm) (can be set to length) | Conventional lengths are 6 meters, 9 meters, 12 meters, 15 meters |

4 | Temperature control section | Zone 3-5 |

5 | control precision | ±2℃ |

6 | Insulation area size | Conventional length is 9 meters, 12 meters |

7 | Water cooling zone size | Conventional lengths are 9 meters, 12 meters, 15 meters |

4 Main features and advantages of the equipment:

1. The furnace is full-fiber aluminum silicate cotton structure, saving electricity and energy saving "1/3, eliminating the old technology, the main goal is to save electricity and energy; continuous work, the annual electricity bill is still relatively large, reducing the cost of use, and increasing profits ;

2. Intelligent PID meter of electric control cabinet + SCR thyristor output, phase shift trigger; PLC control can be designed according to requirements;

3. The company continues to innovate and gradually improve product performance, which is a stable and mature product;

4. The company's "three loyalty" principle, obtain reasonable profits, provide economical products, price concessions, mutual cooperation, mutual benefit, saving electricity and money;

5. Provide satisfactory after-sales service and reflect professionalism and value through service.

5. Structure description:

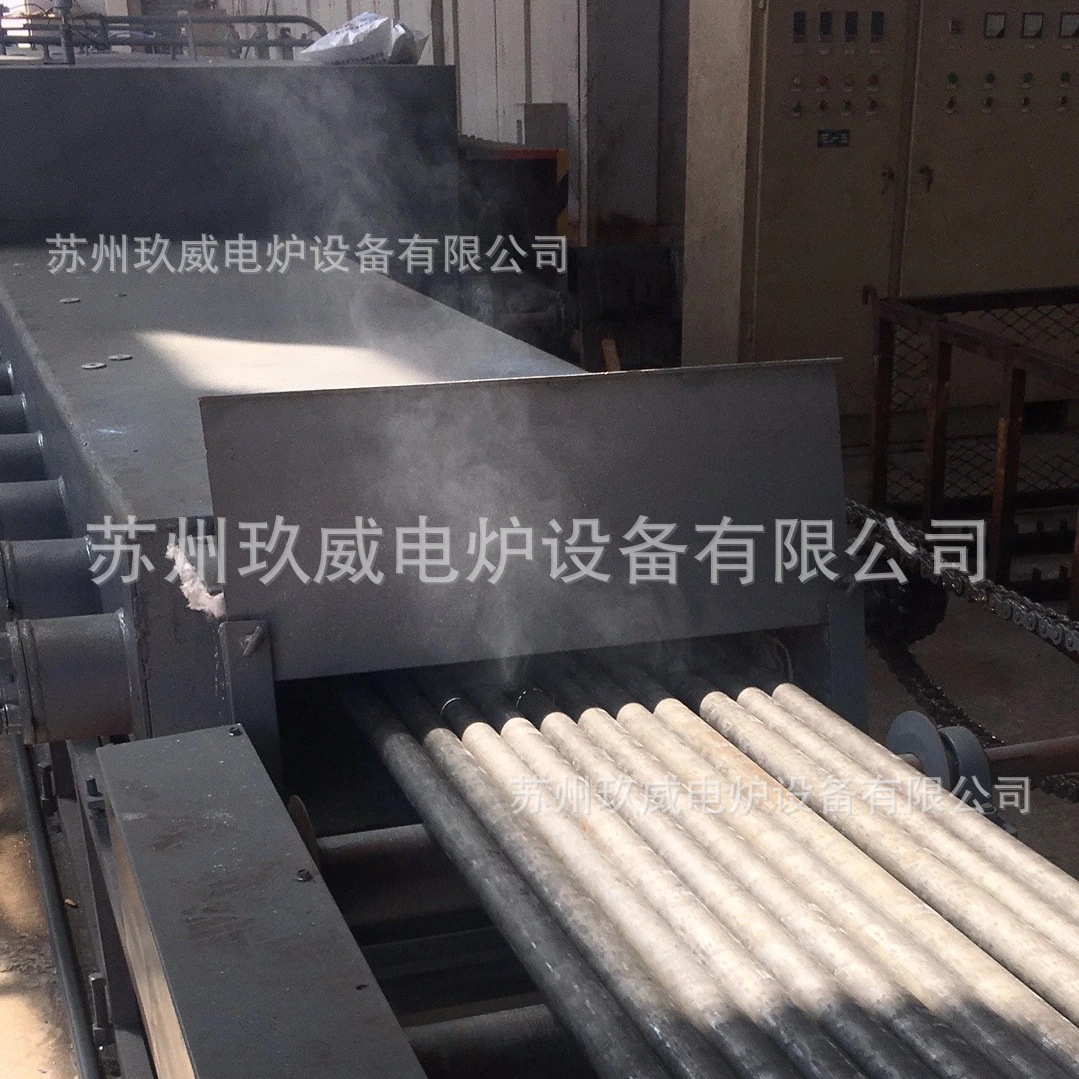

5.1 Furnace structure: The furnace lining adopts a combination of all-fiber aluminum silicate fiber cotton compression modules, and the heating elements are arranged on the upper layer of the furnace top and the lower layer of the furnace bottom. The previous refractory brick and resistance wire structure are eliminated, and the innovative design is fully energy-saving and energy-saving;

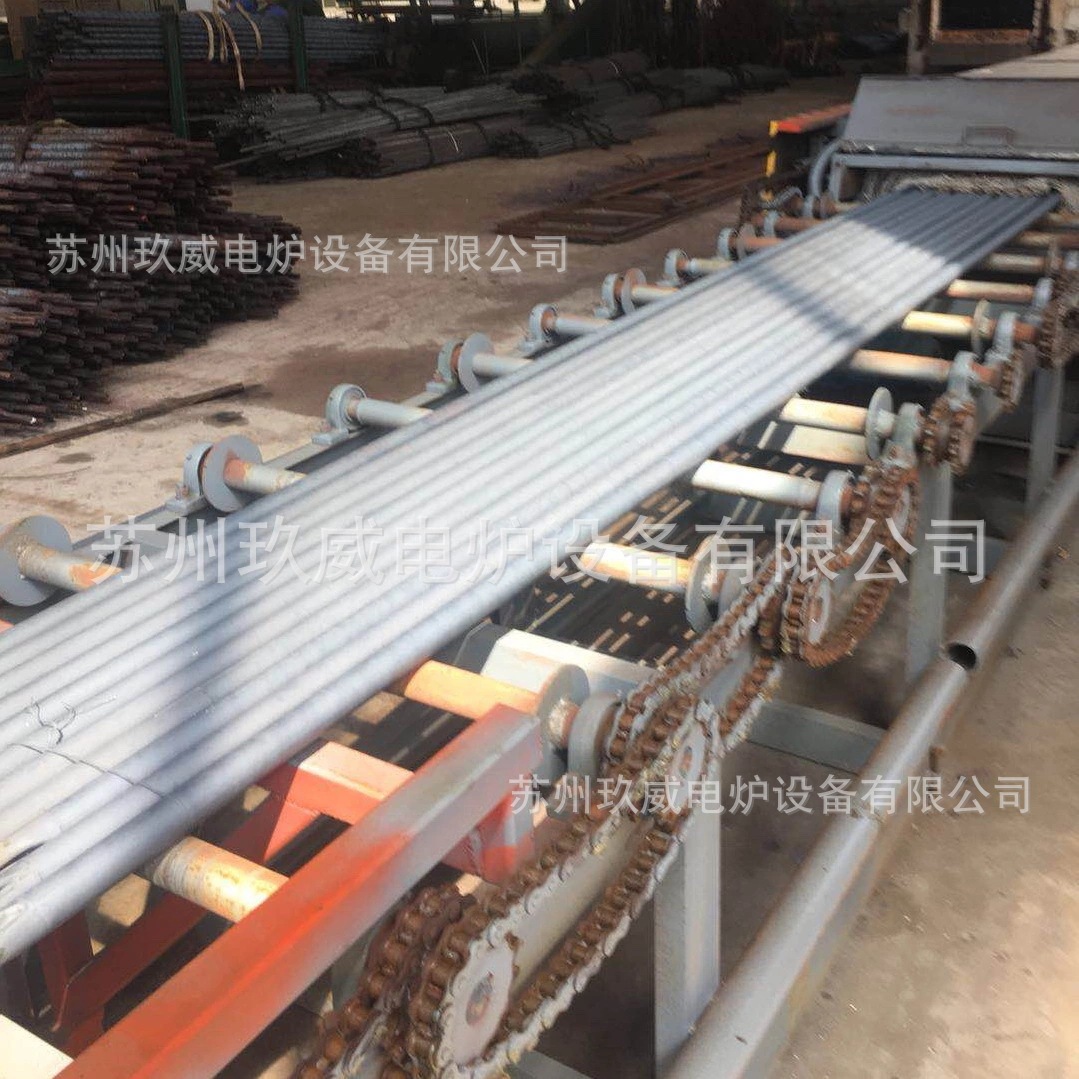

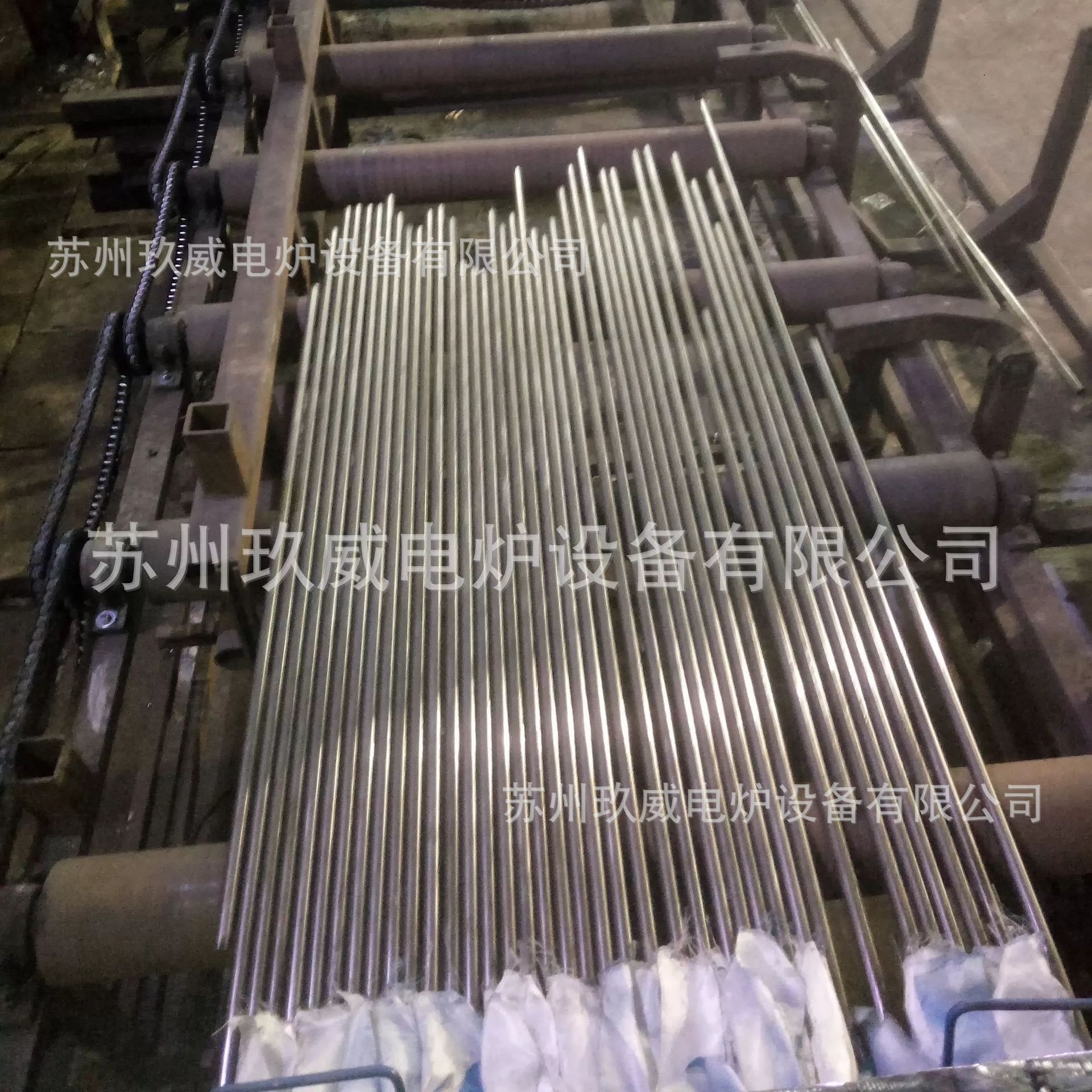

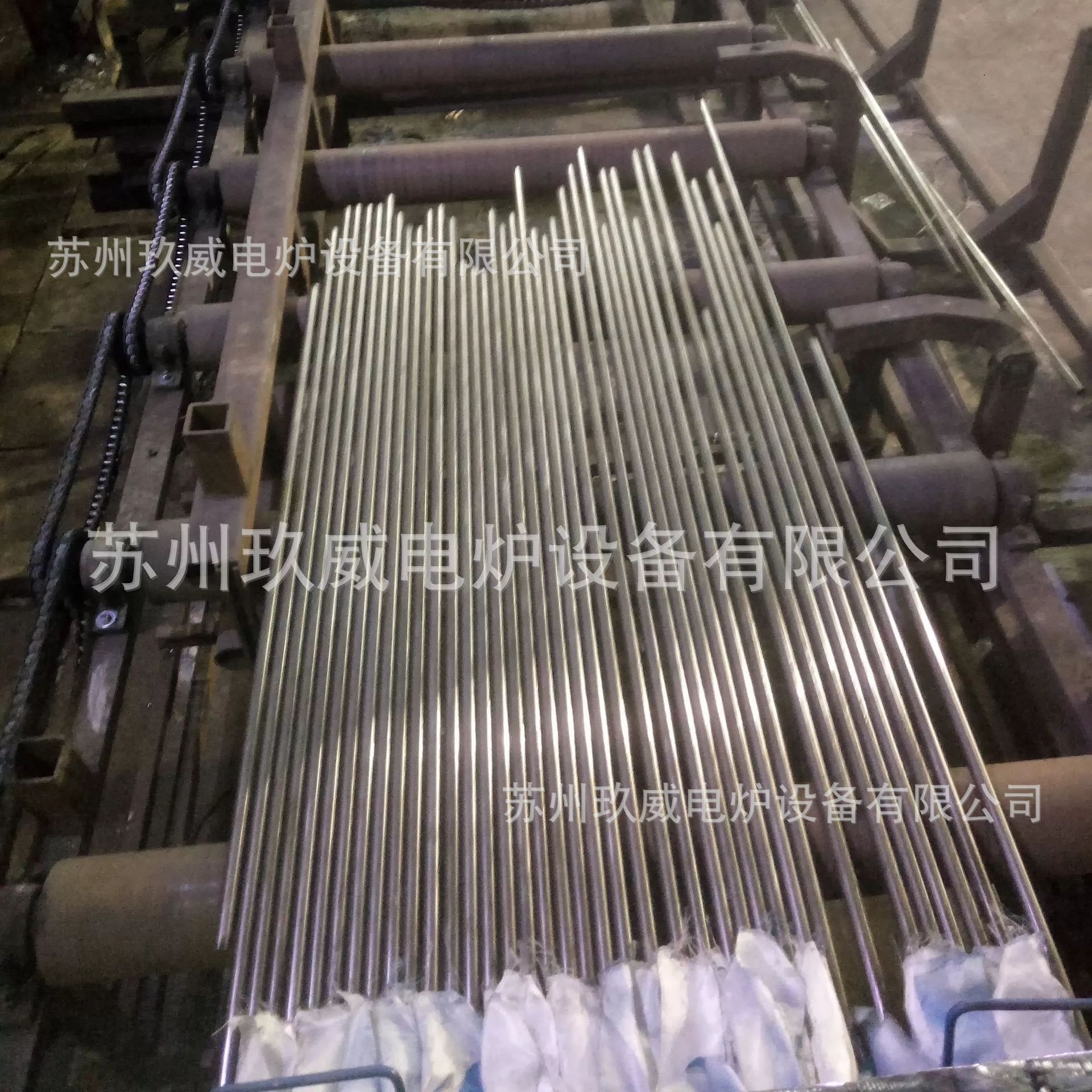

5.2 The roller shaft in the heating zone is made of stainless steel 310S (2520), and the left and right sides are high-temperature sealed bearings and bearing sleeves, flanged; chain sprocket drive, frequency converter speed regulation;

5.3 Control system:

A, the temperature control instrument uses high-precision PID to adjust the temperature control instrument, the control accuracy is ±2℃;

B. The control output is SCR control output, which can adjust the power;

C. In the electrical part of the control system, the primary circuit is equipped with fast fuses and circuit breakers to achieve over-current protection; the secondary circuit is set with an over-temperature alarm and automatically cuts off the heating output, fault alarm reminder, etc.; when preparing for heating, it is necessary to activate each zone" "Heating switch" can be used to heat up and avoid a high-power start when the power is turned on; use sound and light alarm equipment for alarm;

D. According to requirements, PLC+touch screen control can be designed.